Suppository and pessary molding

Suppocire® bases comprise chemically stable fatty acid esters with a narrow melting range. Their physicochemical properties provide numerous formulation and manufacturing advantages, including optimized solidification properties and straightforward scale-up with low, medium, and high throughput manufacturing equipment. Careful selection of the right Suppocire® base ensures optimal physicochemical stability and drug delivery properties, as defined by European Pharmacopeia requirements. In addition, Suppocire® formulations are usually simple binary mixtures of the API dissolved or dispersed in the suppository base. They do not require additional excipients to enhance performance, quality, or stability.

Step 1: Suppocire® melting

Suppocire® pellets are heated at 20 °C above the melting point—indicated in the product technical data sheet—while stirring to ensure the base is thoroughly melted and perfectly homogenized.

Step 2: API addition

The API is added at a temperature above the recrystallization temperature of the base, generally 30–45 °C. Stirring continues during addition of the API to ensure homogeneity.

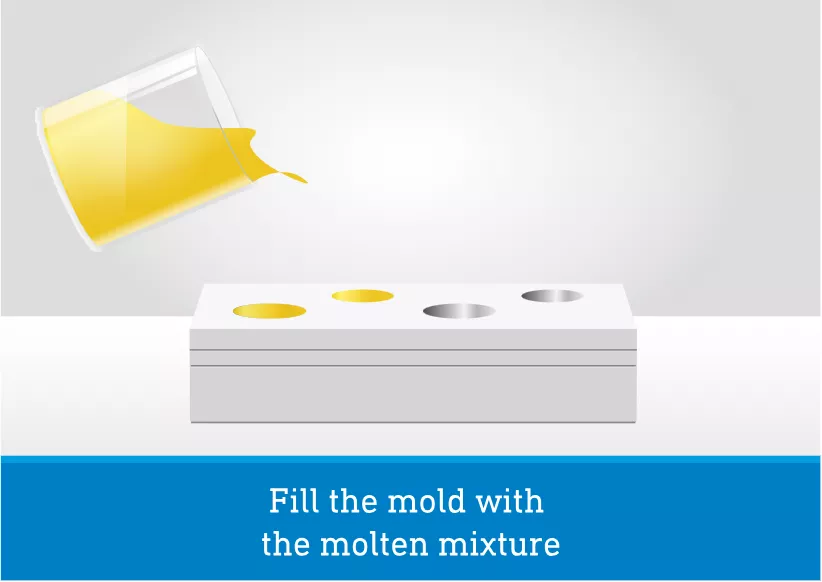

Step 3: Blister filling

The melted, homogenized mixture is poured into the mold at a specific temperature, as determined by a thermorheogram.

A thermorheogram plots viscosity versus temperature and allows you to find the optimal mold or blister filling temperature during production. Since viscosity is a function of the specific formulation ingredients, a thermorheogram is necessary for each formulation. Gattefossé has a thermorheogram for each grade of product in the product page section.

Gattefossé can help you identify the appropriate suppository or pessary base optimized for your API and manufacturing equipment. We also provide advice on formulating to obtain physicochemical stability and performance and solve manufacturing or quality issues. For further information, please contact your local representative.