High shear coating

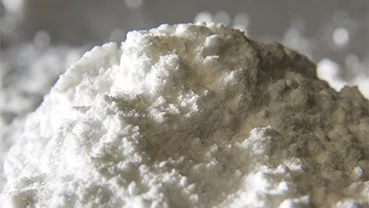

High shear coating is a process in which powdered lipid excipient is mixed with the API in a high shear coater, without external heating. During mixing, frictions are generated. They are responsible for the production of heat and consequently of the partial melting of the lipid excipient. The partially molten lipid excipient coats the drug particles. Upon cooling the lipid coating solidifies and efficiently covers the drug particle, masking its taste.

Advantages of lipid excipients in high shear coating:

- no external heating required

- low process temperature (48°C) ideal for heat sensitive APIs

- solvent-free process

- ideal for hygroscopic APIs

- possible to coat pure API particles

- narrow melting/crystallization range to prevent particle agglomeration

- quick process—no evaporation or downstream curing

- easy equipment cleaning