Hot melt coating

Hot melt coating is a process in which molten lipid excipient is sprayed on to solid particles in a fluid bed coater. The lipid solidifies upon cooling and coats the particles with a thin, homogeneous film. This process can be used for taste masking, protection of sensitive APIs, or modification of drug release profiles.

Advantages of lipid excipients in hot melt coating:

- solvent-free process

- ideal for hygroscopic APIs

- possible to coat pure API particles

- narrow melting/crystallization range to prevent particle agglomeration

- quick process—no evaporation or downstream curing

- easy equipment cleaning

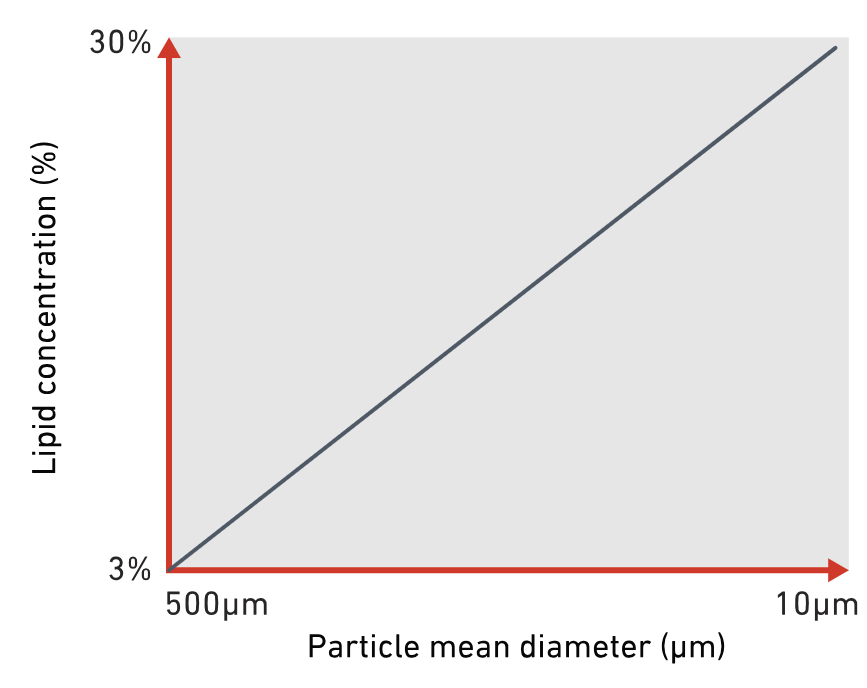

Range of excipients for hot melt coating:

Gattefossé carried out an in vivo study in human subjects comparing the bioavailability of lipid-coated (Precirol® ATO 5) and uncoated acetaminophen. The results showed that the lipid coating has no impact on bioavailability.

Contact Gattefossé to get the study.