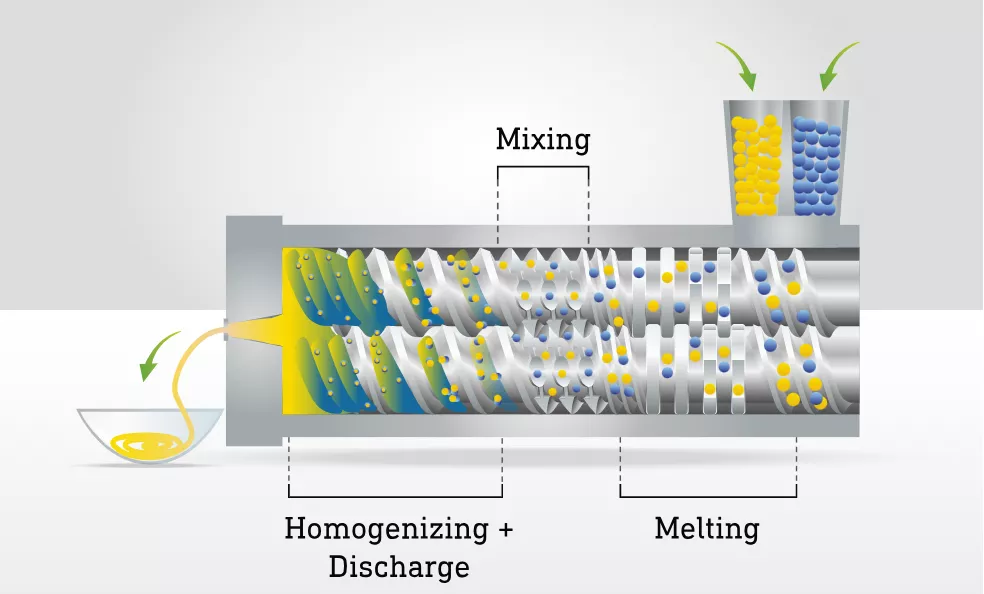

Hot melt extrusion

Hot melt extrusion is a continuous solvent-free technology with precise process control. Lipid excipients are mainly used as matrix formers for modified release, or as solubilizers for solubility/bioavailability enhancement, alone or in combination with polymers.

Advantages of lipid excipients in hot melt extrusion:

- low melt viscosity, resulting in low torque

- low extrusion temperatures (30–75 °C)

- low melting point and instant solidification, thereby avoiding downstream cooling

- high SR drug load potential (up to 90%)

Range of functional excipients for extrusion:

In a collaborative study with the University of Austin, Gattefossé investigated hot melt extrusion using polyvinylpyrrolidone (PVP) as the polymer and Compritol® 888 ATO as the plasticizer and sustained-release agent. The study showed that Compritol® improves the processability of PVP dispersions, reducing extrusion torque and increasing yield.

Harnessing lipids as plasticizers in hot-melt extrusion: a gateway to innovation

Unlocking a new opportunity to use lipid excipients