Formulating W/O Emulsions w/out Worry!

W/O Meets Market Trends

W/O (water-in-oil) emulsions are becoming more and more preferred in the personal care space, particularly regarding color cosmetics and sun care. In color cosmetics, W/O foundations offer better water resistance, long-wear, and high coverage – all the performance qualities a consumer desires – compared to O/W (oil-in-water) formulations. And though W/Si (water-in-silicone) formulations may offer great performance and texture, they do not qualify as natural makeup, making them a less desirable option among younger shoppers. When it comes to sun care, consumers are moving towards mineral options. Sunscreen launches containing zinc oxide increased by 45% from 2014-15 to 2018-19 in North America(1). Zinc oxide is easier to formulate in a W/O than an O/W system. In fact, most inorganic sunscreens are either anhydrous or W/O formulations.

However, formulating can be easier said than done, as there are many challenges that come with making a stable W/O product. W/O systems are more sensitive to other ingredients and require more energy in their processing to ensure stability. There are two key factors to consider when it comes to W/O formulation: oil polarity and electrolyte addition, which may not have any influence or not even be necessary for O/W formulations.

Oil Polarity

The emulsifier you choose has distinctive characteristics that will help you determine the profile of your other ingredients. One trait to consider, that is often overlooked, is polarity. If you are using a more polar emulsifying agent, then your oil phase should consist of more polar oils. Some medium to high polarity oils include C12-15 alkyl benzoate, caprylic/capric triglycerides, octyldodecyl myristate, castor oil, and coco-glycerides, among countless others. On the other hand, if the emulsifier is not very polar, then your oil phase should be more comprised of apolar oils, such as alkanes like squalane, or undecane, tridecane, or silicones if preferred.

Electrolytes Are Included

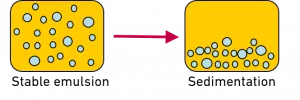

The stability of W/O emulsions can be improved by adding a proper concentration of inorganic salts, such as CaCl2, NaCl, MgCl2, and MgSO4, in the aqueous phase(2). Adding salts to a W/O emulsion inhibits Ostwald ripening, which is where smaller droplets diffuse and deposit themselves onto larger droplets.

Inorganic salts can also lower the interfacial tension at an oil-water interface, thereby improving stability against coalescence and sedimentation(2).

Attractive forces exist within the dispersed phase and can increase their collision frequency(2). This can lead to either coalescence or sedimentation. However, by adding electrolytes to the system, you can lower the attractive forces between water droplets to ensure stability.

Needless to say, electrolytes are absolutely necessary to ensure a stable formula, maintaining the smaller droplet sizes in a consistent, even dispersion.

Easy to Use Emulium® Illustro

Emulium® Illustro is Gattefossé’s gold-winning, naturally derived, high performing, W/O emulsifier that can help you create a natural, stable, and sensorial make-up, sun care, or skincare product! This ingredient has a very large, polar head group and long lipophilic chains that also have polar bonds, as seen by the hydroxide and ester groups.

Because of these polar properties, Emulium® Illustro is more compatible with medium to high polarity oils. But since we’ve engineered this ingredient to be highly compatible and flexible, you may still incorporate apolar oils at certain percentage levels. And as for electrolytes, our R&D team found this ingredient to work very well with 2% MgSO4 or 1% of MgSO4 and NaCl. Check out this video to see how you can make a 2-min emulsion using Emulium® Illustro!

(1) Mintel GNPD

(2) Qiaomei Zhu, Yijun Pan, Xin Jia, Jinlong Li, Min Zhang, Lijun Yin. Review on the Stability Mechanism and Application of Water‐in‐Oil Emulsions Encapsulating Various Additives. (2019)